Overview

The Clarage family of axial fans is custom-designed for specific applications including, but not limited to, tunnel and metro, mining, wind tunnels and the power industry. For the Tunnel and Metro market, the key is smoke control. Various air movement control methods are employed and the equipment must operate at an elevated temperature. In mining, the need is to provide clean air to the shaft or extract the noxious gases, typically at ambient temperatures. Wind tunnel applications are all about the high velocity profile and in the power Industry, the axial fans need to provide high volume at high pressures.

Performance Overview

- IMPELLER SIZES

- Up to 315″ (8,000 mm)

- AIRFLOW

- Single- & Two-Stage Fans – Up to 1,500,000 CFM (2,548,500 m3/hr)

- STATIC PRESSURE

- Single-Stage Fans – Up to 36″ w.g. (8,950 pa)

- Two-Stage Fans – Up to 72″ w.g. (17,901 pa)

- TEMPERATURE RANGE: Up to 1,500°F (815°C)

- Motor Sizes: Up to 15,000 HP (11,185 KW)

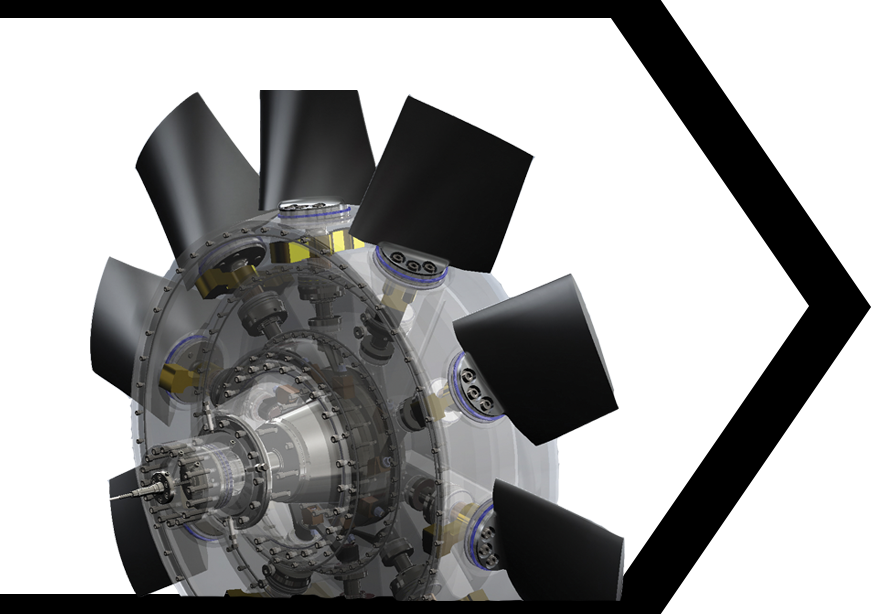

Variable Pitch On-the-Fly Axial Fans

Axial fans are ideally suited for high volumes of air at lower static pressures. Clarage’s variable pitch axial design uses multiple blades attached to a center hub to adjust air performance while in operation. The highly engineered center hub linkages are designed to rotate the blades open and closed to increase or decrease the airflow of the system without ever having to shut the fan off.

Variable pitch axial fans are perfect for induced draft and forced draft fans in the power and mining industry. As airflow requirements change in the system, let the fan do the work. The seamless transition from low to high flow allows the system to adjust while the fan is running.

State-of-the-art engineering and tight machining tolerances on the hub components leads to years of maintenance-free operation on all Clarage variable pitch axial fans. Whether you need a 24″ fan to feed an oxidizer or an 8m fan to run a wind tunnel, Clarage has a solution for you.

- AUTOMATED ADJUSTMENTS CAN BE MADE TO THE BLADE ANGLES WHILE THE FAN IS RUNNING

- AVAILABLE IN SIX BLADE DESIGNS TO FIT THE FAN TO THE EXACT DUTY

- ENGINEERED WITH HIGH QUALITY COMPONENTS FOR YEARS OF DEPENDABLE, LOW MAINTENANCE OPERATION

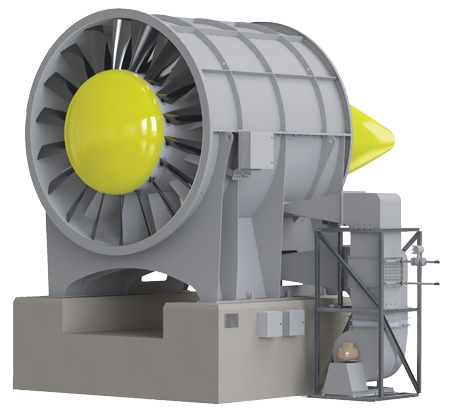

Adjustable-At-Rest Axial Fans

Clarage’s adjustable pitch axial design uses multiple blades attached to a center hub to adjust air performance while in operation. These fans are perfect for induced draft and forced draft fans as required by all industry segments. The equipment can be coupled with variable speed drives to enable operation across a wide spectrum of performance requirements. As airflow requirements change in the system, let the fan and drives do the work. The seamless transition from low to high flow allows the system to adjust while the fan is running by adjusting the fan speed and power consumption.

State-of-the-art engineering and tight machining tolerances on the hub components leads to years of maintenance-free operation on all Clarage adjustable-at-rest axial fans. Whether you need a 24″ jet fan for tunnel smoke control or an 8m fan to run a wind tunnel, Clarage has a solution for you.

- AVAILABLE IN SIX BLADE DESIGNS TO FIT THE FAN TO THE EXACT DUTY

- ENGINEERED WITH HIGH QUALITY COMPONENTS FOR YEARS OF DEPENDABLE, LOW MAINTENANCE OPERATION

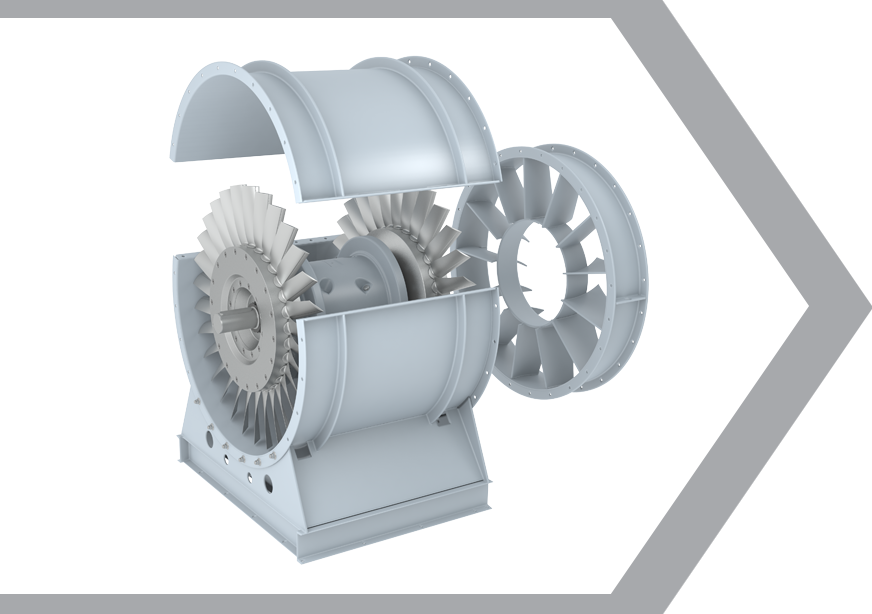

Two Stage Axial Fans

These units are designed for specific contract requirements and would be tailored to the customer’s needs. A two stage axial fan provides high volume at high pressures efficiently. The arrangement of the impellers and motors would be coordinated with the site situation to provide the best solution for the customer.

The concept is a simple one – two fans in series can generate a higher pressure than a single unit at the same volume. Depending on the restrictions of a given site (size and power limitation) the two stage unit may be the best solution for any of the axial family situations.